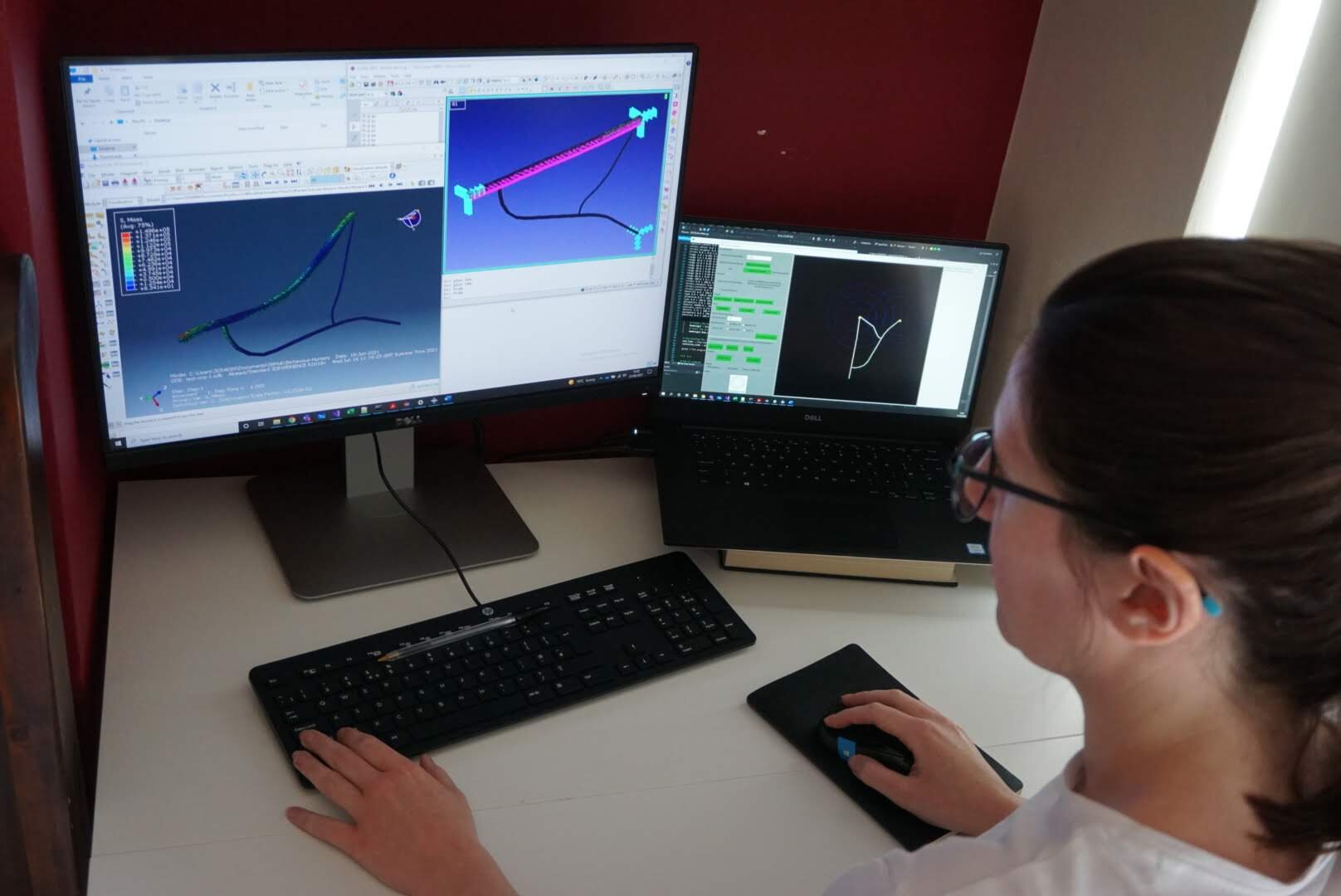

PICTURED: Dr. Imelda Friel from Queen’s University Belfast works on the innovative cyber seed. PC: Queen’s U. Belfast. Released.

Story at a glance…

-

An innovative computer program models the functions of a plant seed to generate new designs.

-

Attached to a cloud system and powered by AI and machine learning, It has the capacity to rapidly develop new concepts and specifications for new technology

-

The work received a £7.5 million grant from the British Government.

There’s an old saying that “*blank doesn’t grow on trees”. Well the recent invention of a “cyber seed” from a team of scientists split between three universities might shake up the old adage in a groundbreaking way.

Queen’s University Belfast, and the universities of Loughborough and York have created a program called RIED (Re-imagining Engineering Design) that combines top machine learning and AI technology with industry-specific specifications to rapidly “grow” new ideas for products or design methods.

The “cyber seed” can be adapted to any manufacturing inputs and outputs, and has attracted financial support from enormous firms like Airbus, Bombardier, Rolls Royce, and others from the medical technology sector, as well as winning a £7.5 million grant from the British government.

The adaptation of biological language is far from a gimmick, and seems to truly be the best method of explaining how the cyber seed works. It’s made up of “genes,” which are simply text descriptions of a product’s desired characteristics and attributes such as size, color, and density. The program uses computer-aided design software to calculate these necessities before creating a 3D model, ready to read and be executed by a 3D-printer or other manufacturing technology.

“The seed generates cells which divide and copy to build up very complex shapes but they only become viable when they meet certain conditions, in the same way nature works,” stated Professor Mark Price at the School for Mechanical and Aerospace Engineering at Queen’s University Belfast.

“For example, if we have a seed for a bicycle and it is being produced by a researcher in Belfast for a customer in Belfast, the available materials may be metal and the end product would be made of aluminum. However, if the same researcher in Belfast is using the cyber seed to create a bicycle for a customer in Asia but the only available material was bamboo, the seed would pick up on this and adapt the design so that a bamboo bicycle could be produced instead.”

One of the chief areas Price and his colleagues see the cyber seed being used is in biotechnology.

Dr. Carmen Torres-Sanchez, a member on the project from Loughborough said: “This flexibility will allow the treatment of new diseases and the rehabilitation of patients who need, for example, a frequent change of orthopedics or an implantable device that releases medication attuned to the patients’ needs along the course of a treatment”.

Indeed instead of traditional inputs like aluminum and bamboo, the seed could grow designs based around a human’s blood type or genetic mutations.

Another area crying out for this technology is circular economies of scale and recycling. The seed could grow modular designs to sustainably repair machine with recycled inputs. Biomaterials like algae-based plastics are emerging as a potential replacement, but instead of relying on small firms with limited human resources and funding, the cyber seed could exponentially increase the rate of discovery for new uses of biomaterials.